Call Us07971189700

Blow Molding Machine

850000 INR/Set

Product Details:

- Product Type Molding Machine

- General Use yes

- Material PET

- Type Water Bottles, Pharmaceutical Bottles, Oil Bottles, Juice Bottles, Cosmetic Bottles

- Computerized Yes

- Automatic Yes

- Blow Moulding Type Stretch Blow Moulding

- Click to View more

X

Blow Molding Machine Price And Quantity

- 1 Set

- 850000 INR/Set

Blow Molding Machine Product Specifications

- Yes

- Grey

- Yes

- PET

- Yes

- 3000 Watt (w)

- Molding Machine

- Water Bottles, Pharmaceutical Bottles, Oil Bottles, Juice Bottles, Cosmetic Bottles

- yes

- Heat Resistant, High Transparency, Full Automatic, High Automatization

- Yes

- Stretch Blow Moulding

- 240 Volt (v)

Blow Molding Machine Trade Information

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 2 Set Per Week

- 6 Week

- Australia, Western Europe, Middle East, Africa, Central America, South America, Asia, Eastern Europe, North America

- All India

Product Description

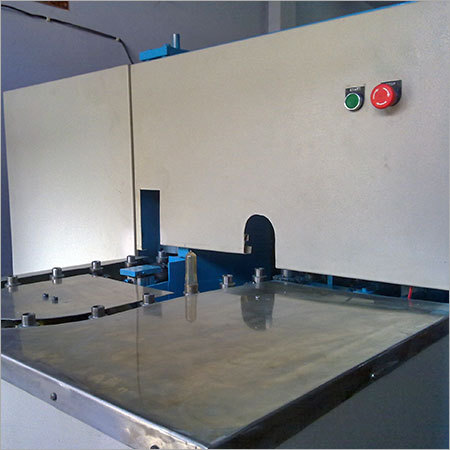

We are highly regarded in the industry for manufacturing and exporting a wide range of Blow Molding Machine. Widely used in packaging industries, these machines are valued for their hassle free and smooth performance. The entire stock of machines is developed at par with the set international standards and norms. Our quality controllers inspect the Blow Molding Machine to ensure its durability and functionality standards.

Features:

- Resistive to corrosion

- Highly efficient

- Excellent operational fluency

Advanced Infrared Heating Technology

The integrated infrared heater ensures uniform and efficient heating of PET material, delivering excellent clarity and consistent bottle quality. This technology minimizes energy waste and accelerates production speeds, making operations more sustainable while maintaining high transparency and precise forming.

Full Automatic Operation for Seamless Production

With computerized controls and full automation, users experience streamlined manufacturing from start to finish. This enables higher productivity and reduces manual intervention, allowing for precise process management and minimized operational errors.

Versatile Applications Across Multiple Industries

Manufacture a range of bottles including water, pharmaceutical, oil, juice, and cosmetic containers. The machine caters to diverse requirements of packaging sectors, making it a preferred choice for businesses seeking flexibility and reliability in their production process.

FAQ's of Blow Molding Machine:

Q: How does the infrared heater enhance the stretch blow molding process in this machine?

A: The infrared heater uniformly warms PET material, ensuring optimal viscosity during the stretch blow molding process. This leads to improved bottle clarity and consistency, reducing reject rates and ensuring the efficient shaping of bottles, regardless of the intended application.Q: What types of bottles can be produced using this automatic stretch blow molding machine?

A: This machine is versatile, capable of producing water bottles, pharmaceutical bottles, oil bottles, juice bottles, and cosmetic bottles. Its design supports the manufacture of varied sizes and shapes required by different industries, all with high transparency and durability.Q: When should I consider using a fully automatic stretch blow molding machine for my production needs?

A: Invest in a fully automatic stretch blow molding machine when your operation demands higher output, consistent product quality, and minimal manual oversight. It is ideal for businesses aiming to meet large-scale supply requirements efficiently and reliably.Q: Where is this blow molding machine manufactured and exported from?

A: This machine is manufactured, supplied, and exported from India by a reputed exporter and supplier, ensuring quality assurance and support for international customers.Q: What is the typical process flow for producing PET bottles using this machine?

A: The process begins with loading PET preforms, which are then heated uniformly via infrared heaters. The machine automatically stretches and blows the material into precise molds, creating bottles with high transparency and heat resistance, all controlled via computerized systems.Q: What benefits does the computerized automatic system offer to the production line?

A: The computerized automatic system guarantees accurate monitoring and control of each production step, enhancing efficiency, reducing human error, and improving overall output consistency. This allows manufacturers to run continuous operations with minimal downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email