Call Us07971189700

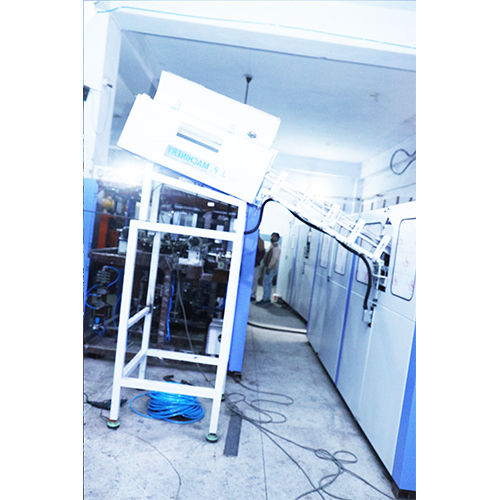

Stretch Blow Molding Machine

850000 INR/Set

Product Details:

- Product Type Molding Machine

- General Use yes

- Material PET

- Type Carbonated Drink Bottles, Water Bottles, Pharmaceutical Bottles, Cosmetic Bottles, Beverage Bottles

- Computerized Yes

- Automatic Yes

- Blow Moulding Type Stretch Blow Moulding

- Click to View more

X

Stretch Blow Molding Machine Price And Quantity

- 850000 INR/Set

- 1 Set

- 850000.00 - 1500000.00 INR/Set

Stretch Blow Molding Machine Product Specifications

- Yes

- Molding Machine

- yes

- 3000 Watt (w)

- Grey

- Stretch Blow Moulding

- Yes

- Carbonated Drink Bottles, Water Bottles, Pharmaceutical Bottles, Cosmetic Bottles, Beverage Bottles

- Yes

- Full Automatic, High Automatization, High Transparency

- 240 Volt (v)

- PET

- Yes

Stretch Blow Molding Machine Trade Information

- Telegraphic Transfer (T/T), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 2 Set Per Week

- 6 Week

- Australia, North America, Middle East, Africa, Western Europe, Central America, South America, Asia, Eastern Europe

- All India

Product Description

Leading the list of topmost organization, we are manufacturing and exporting an impeccable quality of Stretch Blow Molding Machine. Equipped with the latest and advanced components, these machines are known for their excellent performance and maximized productivity. Used for manufacturing jars, cans and bottles, our machines are durable in quality. For further assistance, we deliver the gamut of Stretch Blow Molding Machine to clients' end at the most economical prices.

Features:

- Sturdy structure

- Easy to operate

- Maintenance free service

- Additional savings of 15% on air consumption: optional exhaust air recovery system.

- Reduced maintenance times: to help limit machine shutdowns and boost line productivity.

Advanced Automatization for Versatile Bottle Production

This stretch blow molding machine is equipped with advanced computerized controls for full automation, enabling seamless operation and consistent quality across various bottle types. Whether used for carbonated drinks, cosmetics, pharmaceuticals, or water, it provides precise manufacturing processes and reliable performance, ideal for scalable operations.

Efficient and Transparent Bottle Molding

The machine incorporates infrared heating technology, guaranteeing uniform heating and high transparency in PET bottles. Its robust build, paired with user-friendly controls, allows manufacturers to maximize output while consistently meeting stringent quality standards for clarity and durability.

FAQ's of Stretch Blow Molding Machine:

Q: How does the Stretch Blow Molding Machine enhance PET bottle transparency?

A: This machine uses an advanced infrared heating system to evenly warm PET preforms. Such controlled heating results in uniformly stretched bottles with high transparency and smooth surfaces, making them suitable for products demanding visual appeal and clarity.Q: What types of bottles can be produced with this machine?

A: The stretch blow molding machine is designed to manufacture a broad range of PET bottles, including carbonated drink bottles, water bottles, pharmaceutical bottles, cosmetic bottles, and general beverage bottles, ensuring versatility for manufacturers.Q: When is it recommended to use a fully automatic stretch blow molding machine?

A: A fully automatic machine is ideal for high-volume production environments that require consistent bottle quality and minimal downtime, such as bottling plants and packaging suppliers handling beverages, pharmaceuticals, and cosmetics.Q: Where is this stretch blow molding machine manufactured and supplied from?

A: This machine is manufactured in India and is available for export, making it accessible to exporters, manufacturers, and suppliers worldwide seeking advanced bottle production solutions.Q: What is the blow molding process in this machine?

A: The process involves heating PET preforms with infrared heaters, then stretching and blowing them into bottle molds. The computerized controls ensure precision and uniformity, producing bottles with consistent shapes and transparency.Q: How does automatization benefit users of this molding machine?

A: The fully computerized and automated design streamlines production, reduces labor dependence, increases output efficiency, and ensures consistent product quality, making it an ideal solution for busy manufacturing setups.Q: Can the machine handle different bottle sizes and shapes?

A: Yes, the machine is engineered for flexibility and can be adjusted to produce various sizes and shapes of PET bottles, accommodating changing market requirements and personalized packaging needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email