Call Us07971189700

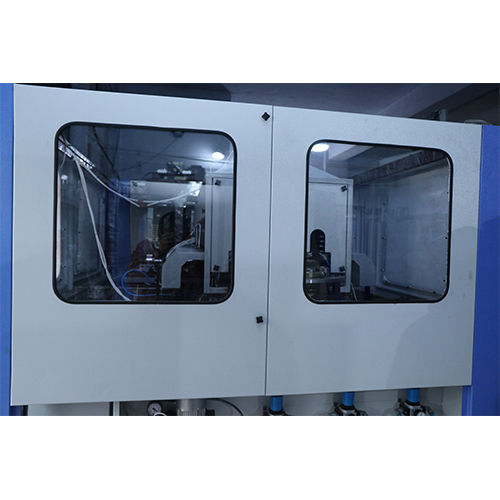

Blow Moulding Machine

Product Details:

- Product Type Blow Moulding Machine

- General Use Industrial production of hollow plastic products such as bottles, containers, and drums

- Material Steel, Stainless Steel

- Capacity 100 ml to 5 liters (variable as per mould design)

- Weight (kg) Approx. 1800 kg

- Type Vertical

- Computerized No

- Click to View more

X

Blow Moulding Machine Product Specifications

- Vertical

- 180 mm

- No

- Approx. 1800 kg

- 160 mm

- 0.8 m/min (approx)

- 2100 mm x 950 mm x 2000 mm

- 220 mm

- Single/Double (customizable)

- Industrial production of hollow plastic products such as bottles, containers, and drums

- 80 kN

- Extrusion Blow Moulding

- Yes

- Steel, Stainless Steel

- 380V / 50Hz

- Blow Moulding Machine

- 1.2 m/min (approx)

- Blue & White

- 100 ml to 5 liters (variable as per mould design)

- 12~15 kW

Product Description

Under the supervision of our veteran professionals, we are manufacturing and exporting a wide array of Air Purifying System. Our systems are precisely engineered by our professionals by using optimum grade components for the process. These systems are designed and developed for the supply of pure and fresh air to the work space. Long lasting in service, the Air Purifying System is delivered at the market leading prices.

Features:

- Ensure constant supply of fresh and pure air

- Electrically operated

- Rust proof finish

Precision & Flexibility with Parison Programming

With parison programming for variable thickness control, this machine provides precision in wall thickness, optimizing material usage across varied product shapes and sizes. The control system ensures consistency for bottles, drums, or containersmaking the unit ideal for manufacturers requiring both flexibility and quality assurance.

Efficiency and Safety in Production Lines

A quick cycle time (12 to 16 seconds), efficient water-cooling, and automatic lubrication minimize downtime and maximize throughput. Essential safety features, including emergency stop functions, safety interlocks, and thermal overload protection, help maintain a secure work environment and reduce production risks.

FAQs of Blow Moulding Machine:

Q: How does parison programming improve product quality in this blow moulding machine?

A: Parison programming allows precise control of the wall thickness during the moulding process. This results in products with consistent strength and reduces material waste, ensuring bottles and containers are manufactured with optimal durability and uniformity.Q: What is the process flow for operating the blow moulding machine?

A: The process begins by feeding molten plastic into the extrusion head, where the programmable parison is formed. Once the parison reaches the correct size, the mould closes, air is blown in to shape the plastic, and water cooling sets the form. After the set cycle time (1216 seconds), the mould opens, and the finished product is ejected.Q: When should I perform maintenance on this blow moulding unit?

A: Routine maintenance is essential for optimal performance. Check and top up the hydraulic oil regularly (average 10 L/min consumption), inspect safety interlocks, and monitor the automatic lubrication system. Scheduled cooling system checks will help prevent overheating and ensure smooth operation.Q: Where is this machine typically used in industrial settings?

A: This blow moulding machine is commonly installed in plastic product manufacturing plantssuch as packaging, beverage, and chemical industriesfor producing hollow items like bottles and drums. Its robust steel build makes it ideal for continuous, heavy-duty use.Q: What are the benefits of the included safety and lubrication systems?

A: The emergency stop, safety interlocks, and thermal overload protection ensure operator safety and prevent machine damage. The automatic central lubrication system minimizes wear and tear, reducing downtime and extending the machines service life.Q: How can the machines capacity be adjusted to produce different products?

A: The mould design determines the product size (100 ml to 5 liters), while the clamping force (80 kN) and customizable cavity quantity (single or double) allow for flexible manufacturing. Simply change the mould and adjust the settings to accommodate various shapes and volumes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email